In recent years, 3D printing has evolved from a cutting-edge technology primarily used in manufacturing and design to a promising tool for revolutionizing healthcare. Pharmaceutical companies and researchers have begun exploring the potential of 3D printing for personalized medicine, and FABRX, a leading company in this field, has taken significant strides in demonstrating how this technology can be integrated into community pharmacies. This article delves into how FABRX is paving the way for pharmaceutical 3D printing, transforming how medications are produced, dispensed, and tailored to individual patient needs.

The Emergence of 3D Printing in Pharmaceuticals

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by adding layer upon layer of material. This technology has been widely used across industries like automotive, aerospace, and healthcare for its ability to produce intricate designs with precision. In pharmaceuticals, 3D printing enables the production of customized medications, allowing for flexibility in drug formulations, dosages, and delivery mechanisms that traditional manufacturing methods simply cannot match.

The concept of pharmaceutical 3D printing was first explored with the creation of “printed pills.” These pills, made layer by layer, can incorporate a variety of active ingredients, excipients, and release profiles, allowing for personalized medications tailored to individual patient needs. This approach has opened the door for more effective treatments, especially in patients with unique health requirements, such as those who suffer from rare conditions or have specific medication sensitivities.

FABRX and the Vision for Community Pharmacy

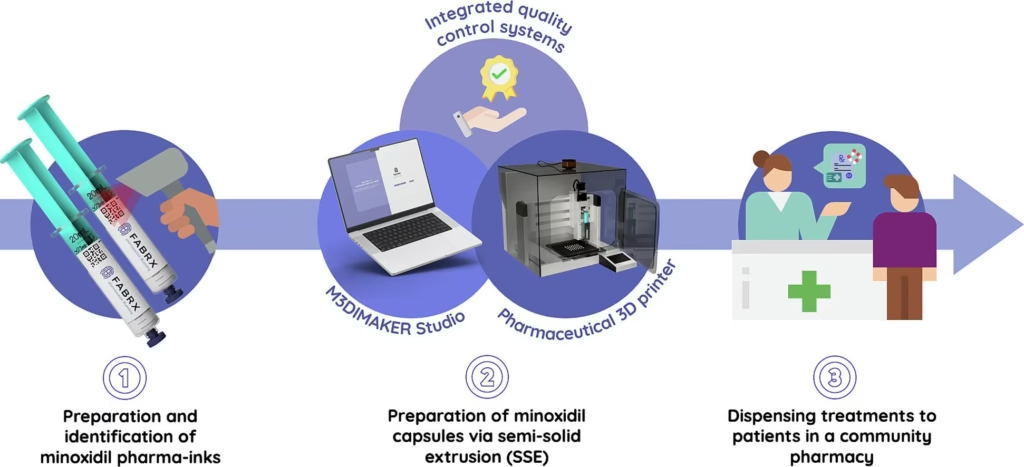

FABRX is a prominent leader in the field of pharmaceutical 3D printing, and the company has set its sights on integrating this technology directly into community pharmacies. Traditionally, community pharmacies have relied on mass-produced medications, which are generally available in standardized dosages and formulations. While this system works for many patients, it leaves a gap for those who require customized treatments—whether due to allergies, difficulty swallowing pills, or specific medical conditions.

FABRX’s goal is to bridge this gap by using 3D printing to produce personalized medicines on-demand. The company envisions a future where community pharmacies are equipped with the technology to print medications that cater to the specific needs of individual patients. By doing so, FABRX seeks to empower community pharmacists to offer a higher level of care, improve patient outcomes, and provide greater access to personalized medicine.

The Technology Behind FABRX’s Pharmaceutical 3D Printing

FABRX has developed an innovative 3D printing platform specifically designed for pharmaceutical applications. This platform utilizes specialized printers and materials that comply with pharmaceutical regulations, ensuring that the printed medications are safe, effective, and reliable.

- Printing Process: FABRX’s 3D printing technology uses a process known as Fused Deposition Modeling (FDM), which involves melting a filament of material and extruding it onto a surface to create a three-dimensional object. In the case of pharmaceuticals, the “filament” is made of pharmaceutical-grade ingredients, including active pharmaceutical ingredients (APIs), excipients (inactive substances), and sometimes biodegradable polymers for controlled drug release.

- Personalization and Customization: One of the most significant advantages of 3D printing in pharmaceuticals is the ability to customize medications to meet the specific needs of patients. With FABRX’s platform, pharmacists can adjust the dosage, formulation, and release characteristics of a drug. For example, a pharmacist could print a pill with a specific combination of medications for a patient with multiple conditions, or a pill with a slower release profile for a patient who requires a gradual effect over time.

- Rapid Prototyping: 3D printing allows for rapid prototyping, meaning that formulations and dosages can be quickly tested and modified. This flexibility is particularly useful for patients who may not respond well to traditional medications or who need alternative drug delivery methods, such as dissolvable tablets or oral films.

- Material Safety and Compliance: FABRX ensures that the materials used in their 3D printing processes meet rigorous standards for pharmaceutical manufacturing. The materials are validated for use in the production of medications, and the technology complies with regulatory guidelines set by authorities like the FDA and EMA. This attention to safety ensures that the final products are not only effective but also safe for consumption.

Benefits of Pharmaceutical 3D Printing in Community Pharmacy

The integration of 3D printing into community pharmacies offers a multitude of benefits, both for patients and for pharmacists. These benefits include:

- Personalized Medicine: The most significant advantage of 3D printing is the ability to tailor medications to individual patients. People with unique health needs, such as those with allergies to certain ingredients, difficulty swallowing pills, or those requiring specific dosages, can receive medications that are specifically designed for them. Personalized medicine can lead to improved treatment outcomes and fewer adverse reactions.

- On-Demand Production: Community pharmacies equipped with 3D printing technology can produce medications on-demand, reducing the reliance on large-scale pharmaceutical manufacturers. This on-demand capability is particularly beneficial in urgent situations or when dealing with rare conditions for which medications may not be readily available.

- Improved Patient Adherence: Personalized formulations, such as those that are easier to swallow or have a preferred flavor, can enhance patient adherence to prescribed treatments. When medications are more convenient and suited to an individual’s needs, they are more likely to follow their treatment regimen, leading to better health outcomes.

- Enhanced Efficiency: With 3D printing, pharmacists can prepare customized medications without the need for complex compounding processes. This leads to more efficient use of time and resources within the pharmacy, allowing pharmacists to focus on other aspects of patient care while still meeting the needs of patients who require customized medications.

- Cost-Effective Solutions: Although 3D printing technology may seem expensive initially, it has the potential to lower costs in the long run. The ability to produce medications on-demand and reduce waste associated with overproduction can result in cost savings for both pharmacies and patients.

Challenges and the Road Ahead

While the potential of pharmaceutical 3D printing in community pharmacies is vast, there are still challenges to overcome before it becomes a mainstream practice. These include:

- Regulatory Hurdles: The pharmaceutical industry is highly regulated, and any new technology must meet stringent safety and efficacy standards. FABRX and other companies must navigate these regulations to ensure that 3D printed medications are approved for use.

- Cost of Technology: While 3D printing has the potential to reduce costs in the long run, the initial investment in equipment and training can be significant. This could present a barrier for smaller pharmacies, especially in less affluent areas.

- Education and Training: Pharmacists must be properly trained to use 3D printing technology effectively. This requires both technical knowledge of the printing process and an understanding of how to design medications that meet the needs of individual patients.

- Public Perception: The public may be hesitant to embrace 3D printed medications due to concerns about their safety and effectiveness. Building trust in this new technology will be crucial for its widespread adoption.

Conclusion

FABRX is at the forefront of an exciting new chapter in pharmaceutical care, demonstrating how 3D printing can transform the way medications are produced and dispensed in community pharmacies. By providing personalized, on-demand medications tailored to individual needs, FABRX is helping to improve patient outcomes and make healthcare more accessible. Although challenges remain, the future of pharmaceutical 3D printing looks promising, and as technology evolves, it may become an integral part of everyday pharmacy practice. Through innovation and collaboration, companies like FABRX are paving the way for a future where personalized medicine is more accessible and efficient than ever before.